Troubleshooting External Hard Drives: What to Do After Applying 19V to 12V HDD

Accidentally applying the wrong voltage to electronic devices is more common than one might think, and the consequences can range from mild annoyance to severe damage. In this blog post, we’ll delve into a specific case of applying 19V to a 12V external hard drive (HDD), discussing the implications of such an incident, potential troubleshooting steps, and solutions that might help in recovering valuable data or restoring functionality.

Understanding External Hard Drives

Before we explore this specific problem, it’s essential to understand how external hard drives function. An external HDD comprises a standard hard disk and an interface that allows it to connect to various devices like laptops, desktops, or gaming consoles.

Components of an External HDD

-

Hard Drive Mechanism: This is the primary component where data is stored. It includes read/write heads, platters, and a spindle motor.

-

Enclosure: This protects the HDD and typically houses additional components like a power supply and circuitry to convert SATA/IDE connections to USB or eSATA.

-

Power Supply: Most external HDDs require a specific voltage to operate, typically 5V for portable drives and sometimes 12V for larger, powered units.

-

Interface Circuitry: This translates the data from the HDD into a format that can be understood by the computer.

Common Voltage Ratings

The voltage ratings for drives can often lead to confusion.

– 5V is common for portable drives

– 12V is generally used in larger, externally-powered drives that utilize 3.5-inch SATA drives.

Errors can occur easily since many power adapters can output multiple voltages, and it’s critical to ensure compatibility before plugging in.

What Happens When You Apply the Wrong Voltage?

Applying 19V, a voltage significantly higher than the rated 12V, can lead to damage or malfunction in various electronic components. Here’s a breakdown of what typically happens:

-

Electrical Overload: Exceeding the voltage rating creates an electrical overload that can damage components, burn out circuits, and result in excessive heat.

-

Heating of Components: The component responsible for regulating voltage/playback data (in this case, the “SH8570DC” chip noted by the user) can heat up rapidly, potentially leading to immediate failure.

-

Permanent Damage: In some cases, the damage isn’t visible—subtle internal components can burn out while the external PCB appears intact.

Initial Reactions and Observations

Symptoms Noted

The user noted that the HDD would not spin up, but Windows detected something when connected. This suggests that while some power is reaching the device, the core functionality is compromised.

PCB Inspection

When inspecting the PCB (printed circuit board), it’s essential to look for:

– Burn marks or visibly damaged components.

– Overheating components (as noted with the SH8570DC).

– Signs of physical damage, such as broken connections or burnt fuses.

If no visible damage is apparent, there could still be micro-level issues, damage to the drive’s firmware, or faults within the chips.

Replacement Strategies

PCB/Chip Replacement

If the damage is limited to the PCB or the chips, replacing them could provide a solution. However, the feasibility of this method depends on several factors:

-

Availability of Compatible Parts: Finding a compatible PCB for your external HDD model can be a puzzle. Manufacturers like Western Digital, Seagate, Toshiba, etc., may offer replacement boards but ensure they work with your specific drive model.

-

Skill Level: Replacing a PCB or chip requires some electronic repair skills, including soldering and an understanding of component functionality. If you’re not comfortable working on electronics, it might be best to leave this to professionals.

-

Cost-effectiveness: Depending on the significance of the data stored and the costs of new parts, you must evaluate whether this route is financially viable.

Data Recovery Services

If you have critical data stored on the HDD, it might be best to seek professional data recovery services. These specialized businesses have the tools and experience to recover data from damaged devices, possibly utilizing more advanced techniques than DIY repairs.

DIY Data Recovery Options

If you’re looking for less expensive alternatives, here are a few DIY options you might consider before seeking professional help:

-

Freezing the HDD: A popular but risky method among data recovery enthusiasts involves sealing the drive in a plastic bag and placing it in the freezer for several hours. The idea is that it might temporarily contract, allowing the platters to align properly. However, this is not a guaranteed success and can introduce moisture.

-

Using a Different Power Source: If your original adapter applied too much voltage, testing the drive with a properly rated 12V adapter might yield some positive results. Occasionally, components can reset if powered with the correct voltage.

-

Testing with Different USB Cables or Ports: Sometimes, issues can be related to connectivity rather than the drive itself. Trying different cables or USB ports can rule that out.

Preventive Measures: How to Avoid This Situation in the Future

-

Labeled Power Adapters: Always label your power adapters’ voltage ratings, especially if you have many devices. Having a clear visual cue can help prevent mistakes.

-

Multi-Voltage Adapters: Consider investing in multi-voltage adapters that allow you to switch settings according to the device, reducing the risk of incorrect connections.

-

Backup Regularly: No appliance is immune to failures. Regularly backing up essential data can mitigate loss when hardware malfunctions happen.

-

Understand Operating Conditions: Familiarize yourself with the specific needs of your HDD. Each model might have different power requirements, especially across brands.

Conclusion

Accidentally applying 19V to a 12V HDD can result in serious consequences, including component damage or data loss. While visually inspecting the PCB may not reveal damages, overheating components signal potential failure. Depending on the damage, replacing the PCB/chip or consulting with data recovery professionals may be necessary. Preventing these situations through careful labeling, using the correct equipment, and regular backups are paramount.

Ultimately, understanding your hardware and taking care can minimize risks and protect against potential data loss and device failures. With diligent care, you can keep your valuable data safe and your devices running smoothly.

Share this content:

Hi there,

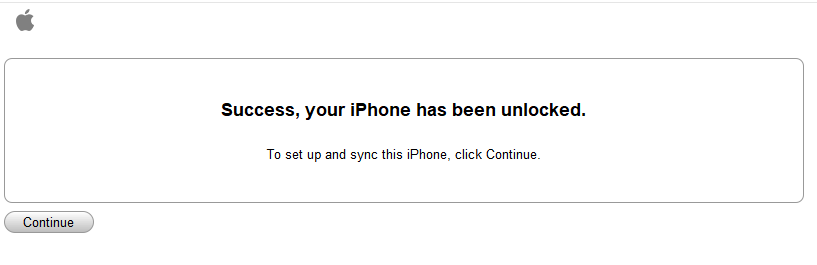

Applying a higher voltage such as 19V to a device rated for 12V can cause significant damage to the internal components, especially the PCB and chips like the SH8570DC you mentioned. If your external HDD is not spinning up but is still detected by Windows, it suggests that power is reaching the device but the main drive components might have suffered damage.

Here are some troubleshooting steps you can consider:

Important: Replacing chips or the PCB yourself is complex